Can payments innovations fix supply chains?

IDEAS BANK

We are living through a global supply chain reset. First, Covid-19 and a volley of geopolitical shocks prompted businesses to reroute their operations for greater resilience. Now, economic pressures have put supply chains under scrutiny once more. Price rises across energy, materials and logistics are driving companies to make cuts and increase efficiency in their internal teams and external supplier networks. Meanwhile, higher interest rates means that businesses have to carefully steward every dollar of working capital or risk missing out on attractive returns.

The logistics sector is looking at a number of strategies to meet these requirements. A crucial one is arguably the most obvious: modernizing the payments process. Traditionally, supply chains have been beset with inefficient, labor-intensive practices. For example, many freight companies in the U.S. still have largely manual workflows. They send paper invoices and get paid via check. This process can be frustratingly slow, with payments taking days or weeks to arrive. Even worse, it exposes companies to a higher risk of fraud, and traps their data which hinders cost-effective decision-making.

An even more serious challenge is reconciliation. “About 20 percent of the time there's a discrepancy, meaning the invoice amount or other details don’t match what was expected in the contract. It can sometimes take up to 60 days to solve the issue because companies aren’t empowered with high-quality data to understand the root-cause,” says Matt McKinney, co-founder and CEO of Loop, a logistics-AI audit and pay solution built for shippers and logistics service providers.

The supply chain is a network of networks and each point of payment friction at every phase adds cost. Ultimately, someone has to pay for the capital that's locked up—they may need to take an expensive bridging loan to make up the shortfall.

“The supply chain runs on data. Friction in the payments is fundamentally a data problem: purchase orders don’t match invoices. This is a bad problem for people to solve but a great problem for AI,” continues McKinney. One strand of innovation is using AI to extract and centralize all supply chain and spend data that is trapped in physical documents and manual workflows. With accurate, centralized data, both sides can easily correct invoice errors and have an understanding of why the issue occurred.

This is something Loop facilitates, and it also allows payments to be made quickly and simply via the optimal method, be it ACH, wire or real-time payments. This is more significant than it might seem. Large companies can have hundreds of people devoted just to processing checks and solving reconciliation issues. These resources could be better deployed elsewhere.

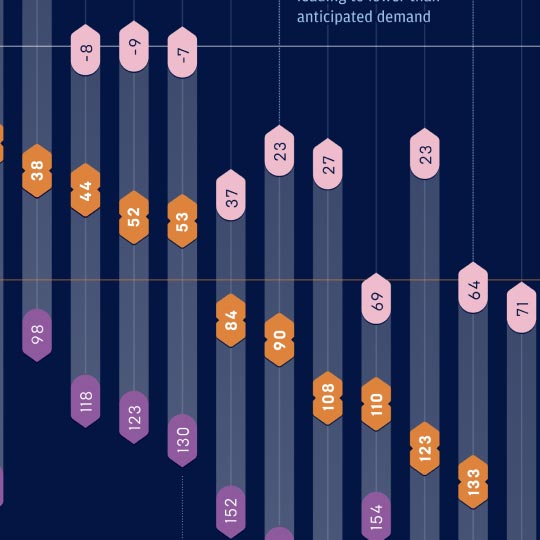

Once payments are digitalized it opens up new financial possibilities. Take dynamic discounting. This is when preferential terms are offered in return for prompt payment. For example, a business could offer to pay a supplier in seven days, rather than the standard 30 days, if that supplier was happy to offer the business a discount in return. This effectively acts as an additional revenue stream for the business, while the supplier gets its money quicker, which can improve its cash flow position. It’s a time-worn idea but in digital form it can be turbocharged, something being explored by working capital solutions provider Taulia. The company uses predictive analytics and artificial intelligence to analyze factors such as company size, revenues, geography and other indicators to better understand a supplier. It then calculates the optimal discount to offer that supplier, so as to maximize potential yield without putting undue stress on that company. In fact, vulnerable suppliers can be actively identified and given more accommodating rates.

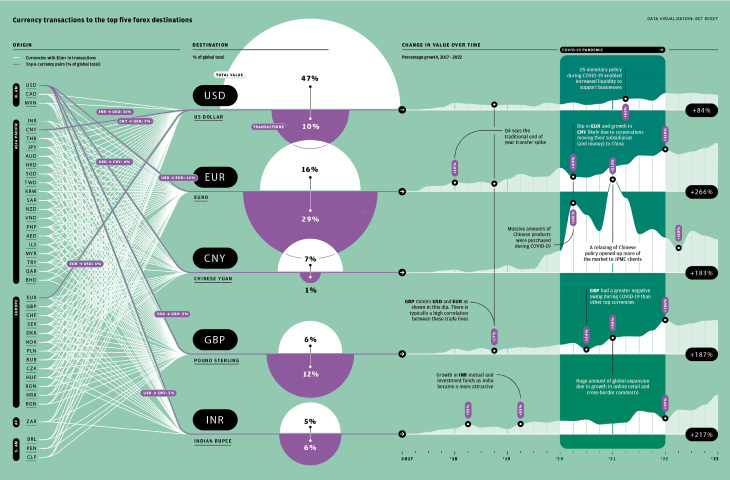

While start-ups such as Loop and Taulia are driving notable improvements in supply chain payments, there is still much to be done. One of the biggest challenges remains cross-border payments, which can be slow and expensive. Some organizations are exploring blockchain as a way of completing transactions around the world at low cost and lightning speed, but this is still in the very early stages. J.P. Morgan’s blockchain division has completed some feasibility testing in this area, but there remain a number of technological and regulatory barriers to its widescale adoption for moving fiat currency.

Still, the progress that is being made in supply chain payments means that businesses are in a better position than ever to find new efficiencies. By using the best digital tools available today to make incremental gains, companies can realise meaningful benefits. Those that get this right might just recast the role of their supply chain altogether. What was once a cost center could become a profit center.

Wherever a business sits in a supply chain, maintaining a healthy flow of payments in and out is critical. Getting suppliers paid on time, or even paid early, promotes efficiencies, satisfaction, and confidence along the entire network of companies involved in providing a product or service.

In contrast, late payments damage trust and efficiency. For companies that require cash to proceed with delivery of products or services, it creates productivity bottlenecks. Longer term, it holds companies back from being able to plan and scale.

“Digital payments are a key tool in preventing late payments. They provide two things which are often missing in the payments chain – transparency and data. A digital, trackable payments process allows suppliers to know exactly when and how they can expect to get paid,” Ian Hill, Director of Product Management – Virtual Cards at payments technology platform Taulia, says.

This certainty allows these businesses to pay their own suppliers downstream, settle taxes, produce accurate accounts, take on new orders, commit to purchases, and make plans – all critical to remaining solvent and in growth.

Supply chain finance is another tool that can cut the risk of late payments and supply chain disruption. It does this by enabling businesses to optimise their working capital, and to bridge periods where they may be awaiting payment or facing a financial challenge. For example, this could look like a business borrowing money at a low rate to pay its suppliers earlier. It can then conserve its own cash, which can be invested at a higher rate to the loan. By deploying a solution like this, the business has made its own funds work harder, earning more interest, and has supported the cashflow of other companies in its supply chain.

Used together, digital payments and working capital solutions offer the ability to bring other supporting financing tools into the equation. For example, a supplier to Company A might be used to net 90-day terms. By deploying a working capital solution, Company A could pay the supplier via trackable, automated digital payments on 30-day terms, increasing payee confidence, loyalty and satisfaction, while optimising their own returns.

Another cashflow-friendly tool which combines data with digital payments technology is dynamic discounting. In this scenario, there is no borrowing. Instead, the supplier offers a discount for early settlement. Data on individual firms helps calculate the optimal discount.

Cashflow problems cause productivity holdups, and so for Taulia, creating as much flexibility in their funding and payments solutions as possible is key. Taulia has recently brought to the market the ability to offer what it calls ‘Flexible Funding’. This gives corporate buyers the ability to choose when they want to use supply chain finance and working capital solutions, and when to use dynamic discounting, with the ability to switch quickly between the two.

For example, a company may be flush with cash one month, and wants to pay its invoices early. Later in the year, it may want to preserve its cash and finance those invoices. Through Taulia’s combination of services and digital tools, the business can optimise its working capital and smooth over natural ebbs and flows in income over the course of the company year.

When it comes to creating a sustainable supply chain, a key focus has always been on transportation, whether it is trying to reduce distance travelled, use cleaner fuels or switch over to electric vehicles. However, one vital area that is often overlooked is materials.

“We keep using the same materials we have used through history. We are changing how we make the materials, we are trying to make process more green, but we are not changing the materials themselves,” says Albert Douer, Chairman and Co-CEO of sustainable plastics company UBQ.

“Yet, every material that we need for our daily lives affects the planet negatively in some way, because at some point we have to extract it,” continues Douer.

Think of the plastics we use in our daily lives, they mainly come from hydrocarbons, while simple building materials like concrete require extensive mining of sand and gravel. The list goes on.

Re-thinking materials

UBQ has a radically different approach. It takes unsorted household waste and through its own patented conversion process, breaks down the organic matter to its component parts and then uses these building blocks to create a bio-based thermoplastic.

“Rather than extracting from the planet, we are utilizing something, that, if left alone, would actually be damaging to the planet,” says Douer.

The material, which comes in pellet form, can be used for a wide range of applications, from packaging to automotive parts to tennis shoes. It can also be an effective substitute for wood in the construction industry, such as for roofing or pallets, meaning less trees need to be cut down.

Disrupting waste disposal

UBQ can also be effective at the other end of the supply chain. To take one example, the UK ships over a million tonnes of waste to continental Europe each year to be incinerated, which contributes to air pollution in the region. UBQ can disrupt this process by locating its plants close to where the waste is being produced. The thermoplastic created can then be sold or exported, bringing in extra revenue to the country. One of the problems that many sustainable materials have had is that they are not economical. But according Douer, “UBQ can compete with all of the fossil-based materials, we have taken cost out of the equation.”

So how can UBQ help the payments industry? “Well J.P Morgan is building a new office building in New York,” says Douer, “think how many desks they have in the space, how many garbage cans? These can all be made with UBQ!”

SOURCES: WWW.JPMORGAN.COM/PAYMENTS-UNBOUND/SOURCES

ILLUSTRATION: VIKTOR KOEN